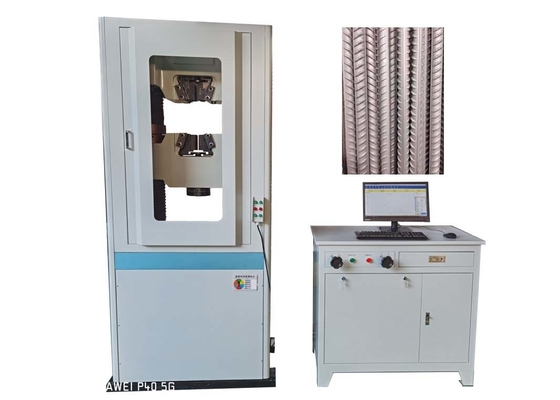

BS 4449 콘크리트 보강용 강철 유압 만능 시험기

작동 원리:

주 기계는 4개의 기둥과 2개의 리드 스크류가 있는 6기둥 프레임 구조를 사용합니다. 상부 크로스빔과 하부 크로스빔은 인장 공간을 형성하고, 하부 크로스빔과 작업대는 압축 공간을 구성합니다. 전기 컨트롤러, 서보 밸브, 로드 센서, 변위 센서, 신율계 및 컴퓨터로 구성되어 폐루프 서보 제어 시스템을 형성합니다. 이 시스템은 시험 과정을 자동으로 정확하게 제어하고 시험력, 변위, 변형과 같은 시험 매개변수를 자동으로 측정할 수 있습니다.

가격 경쟁력:

자체 연구 개발을 강화하고 가공 센터를 설립하여 핵심 부품을 독립적으로 제조합니다. 이를 통해 일관된 품질을 유지하면서 공급망 전반의 비용을 절감할 수 있습니다. 저렴하고 품질이 떨어지는 제품과 달리, 당사의 고품질 제품은 장기적으로 훨씬 더 큰 비용 절감을 제공합니다. 기계 고장률을 최소화하여 고객의 유지 보수 비용을 줄이고 운영 효율성을 향상시킵니다. 이러한 경쟁력 있는 가격과 우수한 품질의 조합은 고객에게 실질적인 이점을 보장합니다.

특징:

고정밀 측정

고정밀 로드 센서, 변위 센서 및 신율계를 갖추어 시험 중 힘, 변위, 변형과 같은 매개변수를 정확하게 측정할 수 있습니다. 힘 값 정확도는 일반적으로 ±0.5%에 도달합니다.

다양한 제어 모드

힘 제어, 변형 제어 및 변위 제어를 포함한 여러 제어 모드를 지원합니다. 시험 중 사전 설정된 프로그램에 따라 다양한 모드 간에 원활하게 전환할 수 있습니다.

광범위한 속도 범위

극도로 낮은 속도에서 비교적 높은 속도까지 무단 속도 조절이 가능하여 다양한 재료 및 시험 유형에 대한 하중 속도 요구 사항을 충족합니다. 속도 범위는 일반적으로 0.05–200 mm/min입니다.

자동 제어 및 데이터 처리

시험 과정은 컴퓨터 소프트웨어를 통해 자동으로 관리되며, 시험 데이터를 자동으로 수집, 기록 및 처리할 수 있습니다. 지정된 비례 신장 강도, 인장 강도, 탄성 계수 및 신장과 같은 시험 결과를 계산하고 실시간 시험 곡선을 표시하고 인쇄된 시험 보고서를 생성할 수 있습니다.

다기능 시험

프리스트레스 콘크리트 강철에 대한 인장 시험 외에도, 고정구 및 보조 도구를 교체하여 기타 금속, 비금속 및 부품에 대한 압축, 굽힘 및 전단과 같은 다양한 기계적 특성 시험을 수행할 수 있습니다.

표준:

ISO 6892, ISO 6934 BS4449, ASTM C39, ISO75001, ASTM A370, ASTM E4, ASTM E8 및 BSEN 표준.

주요 기술 매개변수:

| 모델 |

WAW-600G |

| 구조 |

4개의 기둥과 2개의 스크류 |

|

제어 방식

|

하중 과정 수동 제어, 컴퓨터 자동 데이터 처리 |

| 최대 하중 (kN) |

600kN |

| 하중 정확도 |

≤±0.5% |

| 하중 범위 |

2%-100%FS |

| 등속 응력 제어 범위 |

2-60 (N/mm2•S-1) |

| 응력 속도 오차 |

≤±0.5% |

| 하중 분해능 |

1/600000 |

| 변형 측정 범위 |

2%~100%FS |

| 변형 정확도 |

≤±0.5% |

| 변위 분해능 (mm) |

0.01 |

| 변위 오차 |

≤±0.5% |

| 최대 피스톤 스트로크(mm) |

250 |

| 최대 피스톤 이동 속도 |

0.5-100 mm/min 수동 조정 |

| 크로스헤드 상승 속도 |

300mm/min |

| 최대 인장 시험 공간 |

700mm (맞춤형 가능) |

| 최대 압축 시험 공간 |

600mm (맞춤형 가능) |

| 클램핑 방식 |

유압 클램프 |

| 원형 시편 클램핑 범위 (mm) |

φ13-φ40 mm(13-26,26-40) |

| 평판 시편 클램핑 범위 (mm) |

0-15,15-30 mm |

| 평판 시편 클램핑 폭(mm) |

80 |

| 압축판 크기 (mm) |

200*200 |

| 굽힘 롤러 거리(mm) |

450 |

| 굽힘 롤러 폭 (mm) |

120 |

| 전원 공급 장치 |

3상, AC380V, 50Hz (맞춤형 가능) |

| 무게 및 크기 |

2100KG, 960mm*750*2270mm |

포장 및 배송:

자주 묻는 질문:

Q1. 귀사는 무역 회사입니까, 아니면 공장입니까?

A: 공장 + 무역 (통합), 18년 동안 시험 장비 분야에 집중, 14년 수출 경험.

Q2. 가장 적합한 제품을 선택하는 방법은 무엇입니까?

A: 전문 팀이 어떤 종류의 시험을 해야 하는지, 필요한 사양을 알려주시면 최상의 제안을 해드립니다.

Q3. 배송 기간은 어떻게 됩니까?

A: 대부분의 경우, 우리는 공장에 재고가 있습니다. 재고가 없는 경우, 일반적으로 입금 후 15-20 영업일입니다.

긴급한 필요가 있는 경우, 특별한 조치를 고려할 수 있습니다.

Q4. 맞춤형 서비스를 수락하십니까?

A: 네, 물론 표준 기계뿐만 아니라 요청에 따라 맞춤형 기계도 제공할 수 있습니다.

요구 사항을 주저하지 말고 알려주시면 귀하의 요구를 충족시키기 위해 최선을 다하겠습니다.

Q5. 주문 전에 공장을 방문할 수 있습니까?

A: 네, 저희 공장을 방문하시는 귀하 또는 귀하의 팀을 따뜻하게 환영하며 진심으로 초대합니다. 호텔을 예약하고 공항에서 픽업하는 것을 도와드리겠습니다.

Q6. 보증은 어떻게 됩니까?

A: 일반적으로, 우리의 보증은 보증 기간 내에 1년입니다. 기술 지원 및 부품 교체를 제공할 수 있습니다. 필요에 따라, 엔지니어가 더 나은 서비스를 위해 귀하의 현장으로 갈 수 있습니다.

Q7. 기계 포장은 어떻게 되며, 운송 중에 안전하게 보호됩니까?

A: 저희 기계는 표준 수출용 나무 상자로 포장되어 손상되지 않습니다. 우리는 손상 없이 바다 또는 비행기로 많은 시험기를 해외로 배송했습니다.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!