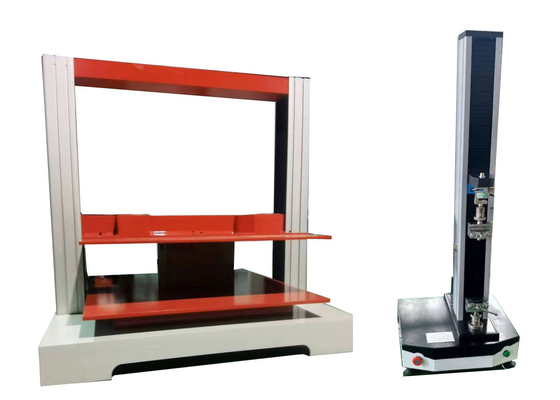

귀하의 테스트 필요에 대한 전자 보편적 테스트 기계의 다양성을 경험

응용 프로그램:

목재의 물리적 및 기계적 특성을 위한 보편적인 테스트 기계는 압축 강도, 휘힘 강도, 팽창 강도, 절단 강도를 테스트하는 필수 테스트 장비입니다.손톱을 잡는 힘, 그리고 그 밖의 것들이죠.

또한 항공우주, 석유화학, 기계 제조, 철, 케이블, 섬유, 섬유, 플라스틱, 고무, 세라믹, 식품, 의약품 포장, 알루미늄 및 플라스틱 파이프,플라스틱 문과 창문GB, JIS, ASTM, DIN 및 ISO와 같은 표준에 따라 최대 시험 힘 값을 포함한 테스트,파열력 값, 양력 강도, 상부 및 하부 양력 강도, 팽창 강도, 골절 연장, 팽창 탄력 모듈, 굴곡 탄력 모듈 및 절단 자동으로 얻을 수 있습니다.

제품 설명:

제어 모드

이 프로그램은 다음과 같이 7개의 제어 모드를 제공합니다.

1- 일정한 속도:

크로스 헤드는 표본이 깨질 때까지 일정한 속도로 위로 또는 아래로 이동합니다. 이 모드에서는 사용자가 속도 (mm/min) 와 깨기 비율 (%) 를 입력해야합니다.

2- 고정 변동:

크로스헤드는 정의된 위치에 도달할 때까지 일정한 속도로 위쪽으로 또는 아래로 이동합니다. 이 모드에서는 사용자가 속도 (mm/min), 유지 위치 (mm) 및 유지 기간 (sec) 을 입력해야합니다.

3. 일정한 로드 속도:

크로스 헤드는 표본이 깨질 때까지 일정한 부하 속도로 위로 또는 아래로 이동합니다. 이 모드에서는 사용자가 속도 (N/min) 와 깨기 비율 (%) 를 입력해야합니다.

4고정 부하:

크로스헤드는 정의된 부하에 도달할 때까지 일정한 속도로 상향 또는 하향으로 움직인다. 이 모드에서는 사용자가 부하 속도 (N/min), 유지 부하 (N), 유지 기간 (sec) 를 입력해야 한다.

5- 일정한 스트레인 인치율:

크로스 헤드는 표본이 깨질 때까지 일정한 스트레인 증가 속도로 위로 또는 아래로 이동합니다. 이 모드에서는 사용자가 속도 (%/min) 및 깨기 비율 (%) 를 입력해야합니다.

6. 일정한 스트레스 Inc. 비율:

크로스 헤드는 표본이 깨질 때까지 일정한 스트레스 증가율로 위로 또는 아래로 이동합니다. 이 모드에서 사용자는 속도 (MPa/초) 와 깨기 비율 (%) 를 입력해야합니다.

7- 일정한 스트레스 인크율 - 일정한 스트레스 인크율:

이 방법은 금속 물질 (철, 강철 등) 을 시험하기에 적합합니다. 금속 물질에 대한 대부분의 표준은 물질의 양이 되기 전에일정한 스트레스 증가율을 사용해야 합니다.이 모드에서 사용자는 일정한 스트레스 증가 속도 (MPa/초) 를 입력해야 합니다.일정한 스트레스 증가율 (%/min), 그리고 깨지기 비율 (%)

기술 매개 변수:

| 모델 |

XWW-10KN |

| 종류 |

이중 나사 |

| 최대 |

10KN |

| 부하의 해상도 |

1/300000 |

| 정확도 수준 |

0.5등급 |

| 힘 |

힘 측정 범위 |

00.5%~100% FS |

| 힘 측정 정확성 |

≤±0.5% |

| 힘 조절 속도 범위 |

0.005--5%FS/S |

| 힘 조절율의 상대적 오류 |

설정 값의 ± 1% 내 |

|

금속 엑텐소미터

|

측정 범위 |

00.2-100% FS |

| 변형 속도 범위 |

00.02~5%FS/S |

| 표시 오류 |

±0.5% 이내 |

| 결의 |

1/300000 |

| 큰 변형 |

측정 범위

|

5mm-1000mm |

| 표시 오류 |

±0.5% 이내 |

| 결의 |

00.001mm |

| 가로 빔 |

가로 빔 이동 해상도 |

00.001mm |

| 가로선속도 범위 |

0.001-500mm/min |

| 테스트 너비 |

400mm (또는 필요에 따라) |

| 통행 가능한 가로 빔 전체 |

900mm |

| 클램프 |

압축판 |

| PC 시스템 |

제어 힘, 이동 및 변형 |

| 전원 공급 |

AC220V; 400w |

| 표준 |

ISO 3346, ISO 3133, ISO 3129, ISO 6237, ISO 9087등등 |

| 무게 |

280kg |

지원 및 서비스:

전자 보편적 시험 기계에 대한 기술 지원 및 서비스

우리는 전문적인 기술 지원 및 전자 보편적 테스트 기계에 대한 서비스를 제공합니다.우리는 고객들이 그들의 필요에 맞춘 최고 수준의 서비스를 받을 수 있도록 최선을 다하고 있습니다.

기술 지원

우리 는 모든 기술 의 질문 에 답 하고 제품 사용 에 대한 지침 을 제공할 준비가 되어 있습니다. 우리 의 숙련 된 기술 팀 은 설치, 운영, 문제 해결 에 도움을 줄 수 있습니다.

수리 서비스

우리는 전자 보편적 테스트 기계에 대한 수리 서비스를 제공합니다. 우리의 기술자는 제품에 발생할 수있는 모든 문제를 식별하고 해결 할 수 있습니다.우리는 또한 고장있는 것을 교체하기 위해 부품과 구성 요소를 공급 할 수 있습니다.

예방적 유지보수

우리는 또한 예방적인 유지보수 서비스를 제공합니다. 우리의 기술자는 기계와 그것의 구성 요소를 검사하여이는 나중에 발생하는 주요 문제의 가능성을 줄이는 데 도움이 됩니다..

교육

우리는 전자 보편적 테스트 기계에 대한 교육 서비스를 제공합니다. 우리의 전문가 팀은 제품 운영 및 유지 보수에 대한 직원을 훈련 할 수 있습니다..

보증

우리는 전자 보편 테스트 머신에 대해 보증을 제공합니다. 보증 기간 내에 문제가 발생하면 제품을 무료로 수리하거나 교체합니다.

사용자 정의:

이 맞춤형 서비스는 고객에게 최적의 전자 보편 테스트 머신을 제공 합니다.크기가 1000mm800mm2000mm, 1000mm의 스트로크, 3-300kN의 테스트 힘 범위. 또한 과부하, 과여행, 과전압 및 과전류 보호 등 다양한 안전 보호 기능을 통합합니다.

전자 보편적 시험 기계는 견인 강도를 측정하기 위해 신뢰할 수 있고 효율적인 시험 기계를 찾는 사람들에게 훌륭한 옵션입니다.향상된 안전 보호 및 사용자 정의 가능한 기능, 고객들은 확실히 그들의 필요에 맞는 완벽한 기계를 찾을 수 있습니다.

포장 및 운송:

전자 보편적 테스트 기계는 거품 포장재, 거품 및 기타 보호 포장재를 사용하여 신중하고 정밀하게 포장됩니다.운송 을 위해 트럭 에 실기 전 에 스키드 에 단단 히 고정 될 것 이다상품은 신뢰할 수 있고 보험에 가입된 화물 운송업체에 의해 배송됩니다.

FAQ:

Q1: 일렉트로닉 유니버설 테스트 머신이란 무엇입니까?

A1: 일렉트로닉 유니버설 테스트 머신 (Electronic Universal Testing Machine) 은 팽창 강도, 압축 강도, 탄력 모듈,그리고 연장.

Q2: 전자 보편적 테스트 기계로 테스트 할 수있는 재료는 무엇입니까?

A2: 전자 보편 테스트 기계는 금속, 플라스틱, 엘라스토머 및 복합재와 같은 다양한 재료를 테스트 할 수 있습니다.

Q3: 전자 보편 테스트 기계는 얼마나 정확합니까?

A3: 전자 보편 테스트 기계는 높은 정확도를 자랑하며 실제 값의 ±0.5% 내에서 측정이 가능합니다.

Q4: 일렉트로닉 유니버설 테스트 머신으로 어떤 종류의 테스트를 수행 할 수 있습니까?

A4: 전자 유니버설 테스트 기계는 팽창 테스트, 압축 테스트, 구부러짐 테스트, 절단 테스트 및 눈물 테스트와 같은 다양한 테스트를 수행 할 수 있습니다.

Q5: 전자 보편 테스트 머신을 사용하는 것의 이점은 무엇입니까?

A5: 전자 보편적 시험 기계 는 재료 의 기계적 특성 을 측정 하기 위한 비용 효과적 인 정확 한 방법 이다. 그것은 또한 사용자 친화적 이며 빠른 결과를 제공할 수 있다.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!