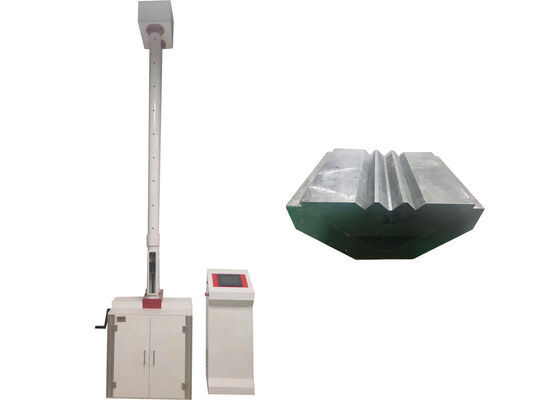

낙하 해머 시험 장비

JB T9389 표준에 따라 파이프 및 경질 플라스틱 시트의 낙하 중량 인열 충격 시험을 제공합니다.

제품 요약

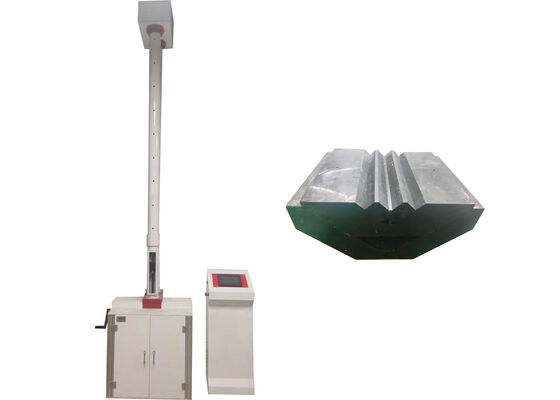

낙하 중량 충격 시험기는 다양한 파이프(PVC-U 급수관, 하수관, 저압 급수관, 저압 수송관, 코어층 발포 파이프, 이중벽 골판지 파이프, PE 급수관 포함), 판 및 경질 플라스틱 시트의 외부 충격 저항을 평가하도록 특별히 설계되었습니다.

이 제품은 산업 표준 JB/T 9389 낙하 중량 충격 시험기 기술 사양 및 ASTM, ISO, BS와 같은 국제 표준을 완벽하게 준수하여 시험 결과가 정확하고 신뢰할 수 있으며 글로벌 산업 요구 사항을 준수하도록 보장합니다.

준수 표준

ASTM D2444, ISO4422, ISO3127, BSEN1411 및 BSEN744.

장비 특성

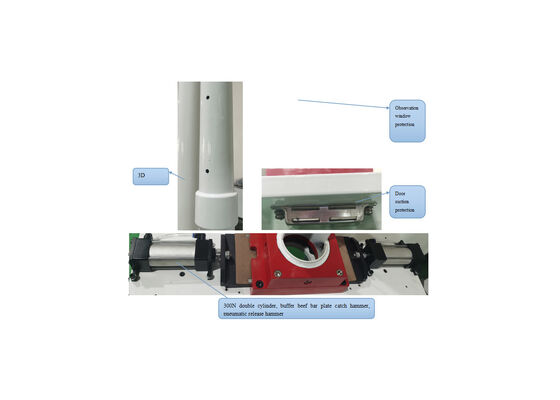

3단계 안전 보호

- 1단계: 샘플 챔버 도어 안전 보호

- 2단계: 관찰 창 안전 보호(일시적으로 미장착)

- 3단계: 상한 및 하한 안전 보호

급속 리프팅 기능

고토크 스테퍼 모터를 장착하여 최대 250mm/s의 리프팅 속도를 달성하여 효율적인 시험 사이클 최적화를 위해 8초 만에 2미터 리프팅 높이를 구현합니다.

지능형 호버링

다단계 속도 제어 알고리즘을 채택하여 기계는 편차 없이 부드러운 해머 위치 지정을 보장하여 안정적인 데이터에 대한 안정적인 시험 조건을 유지합니다.

배기 구조가 있는 최적화된 해머 튜브 설계

낙하 해머 튜브는 3D 모델링을 통해 설계되었으며, 충격 중 공기 저항을 최소화하기 위해 배기 구멍이 통합되어 있습니다. 또한 튜브의 구조적 고장 및 변형을 방지하기 위해 향상된 해머 튜브 클램핑 구조를 갖추어 장기간의 작동 안정성을 보장합니다.

공압 해머 클램핑 및 릴리스 시스템

기존의 전자기 해머 메커니즘을 대체하여 이 시스템은 300N 장행정 이중 실린더를 갖춘 고강도 공압 구조를 채택합니다. 해머 표면에는 안정적인 충격을 보장하고 시료 손상을 방지하기 위해 고무 패드가 장착되어 있습니다. 공압 릴리스 설계는 케이블 피로 및 전기 누출 문제를 근본적으로 제거하는 동시에 공압 자동 잠금 메커니즘은 안전하고 신뢰할 수 있는 작동을 보장합니다.

통합 및 모듈식 설계

- 기계 부품: 표준화된 공정, 모듈식 설치, 경량 설계 및 높은 구조 강도를 실현하는 표준 알루미늄 합금 프로파일 조립을 채택합니다.

- 전기 부품: 7인치 터치 스크린 및 Delta PLC로 구성되어 직관적인 작동과 안정적인 제어 성능을 보장합니다.

프리미엄 구성 요소 품질

모든 핵심 구성 요소는 신뢰성을 위해 국제적으로 소싱됩니다.

- 실린더: Adker 브랜드

- 터치 스크린: Delta 브랜드

- PLC: Delta 브랜드

- 전원 공급 장치: Taiwan Mean Well 브랜드

이 기계에는 누출 방지(전기/물), 단락 방지, 정전기 방지, 간섭 방지, 정전 방지 및 오작동 방지 기능을 포함한 포괄적인 안전 보호 조치가 장착되어 있습니다.

높은 자동화 수준

이 기기는 자동 영점 보정, 해머 리프팅, 해머 릴리스 및 시험 실행을 수행하여 워크플로우를 간소화하고 수동 개입을 줄입니다.

기술 매개변수

| 모델 |

XJL-450M |

| 주변 온도 |

10℃-35℃ |

| 낙하 해머 품질 |

0.5kg-15kg |

| 해머 직경 |

D25mm, D90mm |

| 낙하 높이 |

50mm-2000mm, 오차 ≤ ±2mm |

| 샘플 직경 |

Φ10mm-Φ450mm |

| 고정구 중심에서 충격 중심의 편차 |

≤2mm |

| V형 지지 |

120° |

| 소스 |

220VAC ±10% |

| 외형 치수 |

730mm × 700mm × 3660mm |

| 순중량 |

310kg |

구성 인벤토리

| 이름 |

수량 |

| 호스트 |

1세트 |

| 전기 캐비닛 |

1세트 |

| 해머 본체 |

1세트 |

| 무게 |

1세트 |

| 전원선 |

1개 |

| V형 지지 |

2개 |

| 작동 도구(렌치) |

1세트 |

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!