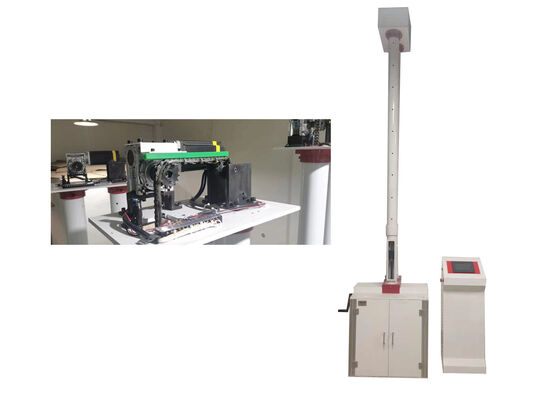

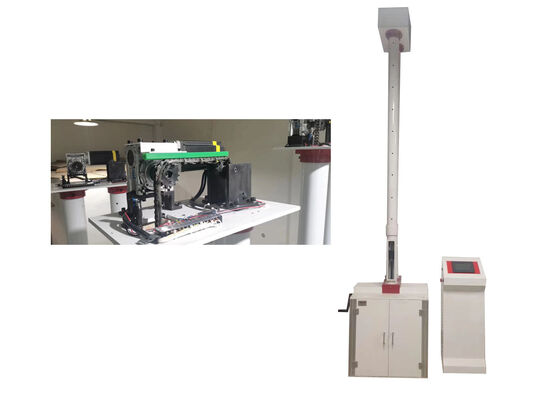

정확한 충격 강도 측정을 위한 낙하 망치 시험 장비

이 테스트 기계는 플라스틱 파이프, 플라스틱 시트 및 비금속 물질의 외부 부하 충격 강도 테스트를 위해 광범위하게 사용됩니다.시험 표본은 정해진 질량과 모양의 떨어지는 망치 (drop hammer) 로 영향을 받으며, 미리 정의된 높이에서 표본의 둘레를 따라 지정된 위치에 놓습니다.이 프로세스는 제품 대량 또는 추출기 생산 실행에 대한 진정한 영향률 (TIR) 의 정확한 추정을 가능하게합니다.

허용되는 최대 TIR:10% (산업 품질 관리 표준에 맞추어)

전문 품질 검사 도구로서 건설 산업, 제조 기업, 화학 부문, 대학,그리고 다른 연구개발 또는 품질 관리 기관.

준수 표준

GB/T14152, GB/T10002.1, GB/T5836.1, GB/T13664, GB/T16800, ASTM D2444, ISO4422, ISO3127, BSEN1411 및 BSEN744

장비 특성

3단계 안전 보호 시스템

- 레벨 1: 방문 안전 보호 샘플

- 레벨 2: 전망 창문 안전 보호 (임시적으로 장착되지 않습니다)

- 레벨 3: 상부 및 하부 이동 제한 안전 메커니즘

이 다층 보호 장치는 전체 시험 주기에 걸쳐 운영자와 표본의 안전을 보장합니다.

고속 승강기

높은 토크 가동 모터 를 탑재 한 이 장치 는 250 mm/s 의 최고 들어올림 속도 를 달성 한다. 이 장치 는 단지 8 초 에 지점 0 에서 2 미터 까지 망치를 올릴 수 있다.테스트 사이클 시간을 크게 줄이고 전반적인 효율성을 높입니다..

정밀 헤버링 시스템

다단계 속도 조절 프로그램을 사용 하 여, 기계는 제로 오프셋과 함께 부드럽고 정확한 망치 위치 를 보장 합니다. 이 안정성 은 일관성 있는 시험 조건 을 뒷받침 합니다.신뢰할 수 있고 재생 가능한 데이터 결과를 제공하는 것.

배기가스 구조와 함께 향상 된 드롭 해머 튜브

떨어지는 망치 튜브는 3D 모델링을 통해 설계되었으며, 망치 하락 과정에서 바람 저항을 최소화하기 위해 환기 구멍과 통합되었습니다.그것은 또한 튜브 변형 또는 기능적 고장을 방지하기 위해 강화 된 클램핑 메커니즘을 통합, 장기적인 운용 견고성을 보장합니다.

공기학적인 망치 클램핑 및 풀기 메커니즘

기존의 전자기 망치 설정을 대체하여, 시스템은 300N의 긴 스트로크 이중 실린더가 장착된 고압 공기 구성을 채택합니다.망치 얼굴은 고무 힘줄 패드를 장착, 안정적 인 충돌 힘을 보장하고 샘플 손상을 방지합니다. 클램핑 및 풀기 기능 모두 공기 기술을 활용하여 케이블 마모, 와이어 부러짐,그리고 전기 누출. 내장 된 공기 자동 잠금 장치 안전 하 고 신뢰할 수 있는 운영을 보장 합니다.

통합 모듈 구조

- 기계적 조립:표준 알루미늄 합금 프로필 구조를 활용하여 표준화 된 프로세스, 모듈형 설치, 가벼운 디자인 및 높은 구조 강도를 가능하게합니다.

- 전기 제어 장치:7인치 터치 스크린과 델타 PLC로 구성되어 사용자 친화적인 조작, 안정적인 제어 성능 및 간편한 유지보수 기능을 제공합니다.

고품질 부품 선택

모든 핵심 부품은 뛰어난 신뢰성과 성능을 위해 전세계에서 구매됩니다.

- 실린더: Adker 브랜드

- 터치 스크린: 델타 브랜드

- PLC: 델타 브랜드

- 전원 공급 장치: Mean Well (타이완, 중국) 브랜드

기계는 전기 누출 보호, 단축 방지, 반 정적 조치, 반 간섭 기술,전력 고장 보호전기, 기계 및 소프트웨어 측면을 포함하는 오작동 예방.

고급 자동화 능력

이 장치는 자동 제로 포인트 캘리브레이션, 자동 망치 높임, 자동 망치 방출 및 자동 테스트 실행을 포함하는 끝에서 끝까지 자동화를 자랑합니다.이것은 수동 참여를 줄입니다., 테스트 효율성을 향상시키고 인간 오류를 완화합니다.

기술 매개 변수

| 매개 변수 |

사양 |

| 모델 |

XJL-450M |

| 실내 온도 |

10°C~35°C |

| 떨어뜨리는 망치 품질 |

0.5kg-5kg |

| 망치 지름 |

D25mm, D90mm (개인화) |

| 낙하의 높이 |

50mm-2000mm, 오류≤±2mm |

| 표본의 지름 |

Φ10mm-Φ450mm (개인 조정 가능) |

| 타격중심과 고정장치 중심의 오차 |

≤2mm |

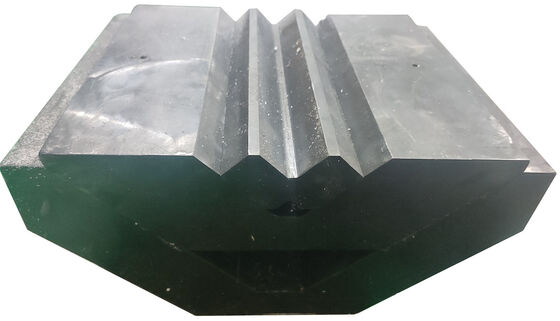

| V형 지지기 |

120° |

| 전원 공급원 |

220VAC±10% |

| 윤곽 차원 |

730mm × 700mm × 3650mm |

| 순중량 |

300kg |

표준 구성

| 구성 요소 |

양 |

| 호스트 |

한 세트 |

| 전기 캐비닛 |

한 세트 |

| 망치 몸체 |

한 세트 |

| 전력 선 |

한 조각 |

| V형 지지기 |

두 조각 |

| 조작 도구 (프렌치) |

한 세트 |

자주 묻는 질문

Q1: 떨어지는 망치 충돌 테스트 기계의 최대 충격 에너지 범위는 무엇입니까?

A1: 표준 모델은 0.5-50 J의 충격 에너지 범위를 제공하며 고강도 재료 테스트를 위해 선택적으로 100 J까지 확장됩니다.그것은 플라스틱 파이프에 대한 다양한 테스트 요구 사항을 충족시키기 위해 조정 가능한 에너지 수준을 지원, 잎, 비금속 물질.

Q2: 사용 가능한 떨어지는 높이와 망치 질량 사양은 무엇입니까?

A2: 조정 가능한 떨어지는 높이는 50-2000mm (정밀 1mm ±) 에서 다양합니다. 망치 질량은 0.1kg의 증가량으로 구성되며 표준 옵션은 0.ISO 3127 및 ASTM D 2444과 같은 일반적인 시험 표준을 다루는 2kg ~ 10kg.

Q3: 기계의 떨어지는 높이와 충돌 힘 조절이 얼마나 정확합니까?

A3: 떨어지는 높이의 정확도는 설정 값의 ±0.1% (또는 ±1 mm, 어느 값이 더 작느냐에 따라) 이다. 공기용 풀기 메커니즘은 초기 속도 오차가 0을 보장한다.힘 감지 시스템 (선택) 은 ± 1%의 충격 힘 정확도를 FS 즈음으로 테스트 데이터의 신뢰성을 보장합니다..

Q4: 기계는 어떤 안전 보호 메커니즘을 가지고 운영 위험을 방지 할 수 있습니까?

A4: 3단계 안전 시스템을 갖추고 있습니다: 1 샘플 챔버 잠금 (문 열리면 기계는 멈춥니다); 2 상부/하부 이동 제한 스위치; 3 비상 정지 버튼.떨어뜨리는 망치 튜브는 또한 높은 에너지 충돌 때 구조적 손상을 방지하기 위해 강화.

Q5: 기계는 국제 테스트 표준과 호환되며 어떤 재료를 테스트 할 수 있습니까?

A5: ISO 3127, ASTM D 2444, GB/T 14152 및 BS EN 14411 표준에 완전히 적합합니다. 적용 가능한 재료는 플라스틱 파이프 (PVC, PE, PP), 플라스틱 시트, 딱딱한 비금속 복합재,그리고 외부 충격 강도 평가를 필요로 하는 다른 재료.

Q6: 기계의 자동화 수준은 무엇이며 테스트 데이터를 자동으로 기록 할 수 있습니까?

A6: 완전한 프로세스 자동화를 지원합니다: 자동 제로 포인트 캘리브레이션, 망치 들어 올림, 위치, 풀림 및 테스트 결과 계산. 7 인치 터치 스크린과 PLC를 갖추고 있습니다.최대 10개까지 저장할 수 있습니다.,000 시험 기록 (충격 에너지, 떨어지는 높이, TIR 값) 및 엑셀/CSV 형식의 수출 데이터

Q7: 주요 부품의 사용 기간은 얼마나 길으며 어떤 유지보수가 필요합니까?

A7: 핵심 부품 (압기 실린더, 스테퍼 모터, PLC) 은 ≥50,000 시험 주기의 사용 기간이 있습니다. 일상 유지 보수에는 안내 레일의 월간 윤활유가 포함됩니다.밀폐 고리의 분기 검사, 그리고 떨어지는 높이와 망치 질량의 연간 캘리브레이션

Q8: 기계가 정상적으로 작동하려면 어떤 환경 조건이 필요합니다?

A8: 작동 온도: 10-35 °C; 상대 습도: ≤85% (비 응축); 전원 공급: AC 220V±10% 50Hz (또는 110V±10% 60Hz, 사용자 정의)작업 부위에 강한 전자기 간섭이나 진동이 없습니다..

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!