자주 묻는 질문

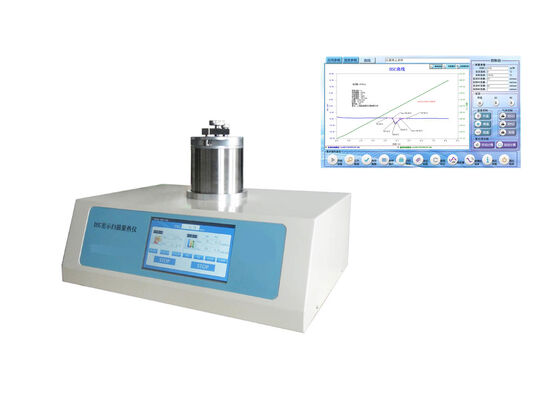

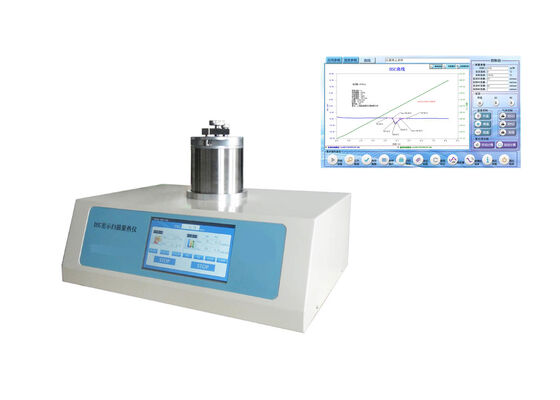

Q1: DSC 기계의 핵심 작동 원리는 무엇입니까?

DSC 기계는 샘플과 무활성 기준 물질 사이의 열 흐름 차이를 측정하여 작동합니다. 둘 다 프로그래밍 된 온도 사이클 (열기, 냉각,또는 동열)이것은 가열과 관련된 물리 화학적 변화의 수치 분석을 가능하게합니다. 예를 들어, 단계 전환, 녹음, 결정화 및 열 분해.

Q2: DSC 기계는 어떤 주요 물리 화학적 특성을 테스트 할 수 있습니까?

유리 전환 온도 (Tg), 녹는점 (Tm), 녹는 엔탈피, 결정화 행동, 결정화 엔탈피,단계 전환 엔탈피, 열 안정성, 경화/교환 정도, 산화 유도 기간 (OIP).

Q3: 표준 DSC 기계의 전형적인 온도 범위와 온도 정확도는 무엇입니까?

표준 모델은 -150 °C에서 700 °C까지의 온도 범위를 제공합니다. 고온 변종에서는 1500 °C까지 확장 할 수 있습니다. 온도 정확도는 ±0.1 °C이며 온도 해상도는 최대 0.01 °C~프로그램된 온도 주기의 정확한 제어.

Q4: 어떤 재료가 DSC 테스트에 호환됩니까?

그것은 폴리머 (플라스틱, 고무, 섬유), 무기 물질, 의약품, 식품 성분, 기름과 지방, 복합재,그리고 다른 소재는 열 특성을 분석해야 합니다., 품질 관리 및 장애 분석 시나리오.

Q5: DSC 기계는 국제 테스트 표준에 부합합니까?

네, 주요 국제 표준 ISO 11357 (폴리머), ASTM E967/E968 (일반 DSC 방법), GB/T 19466 (플라스틱),그리고 USP <891> (의약품).

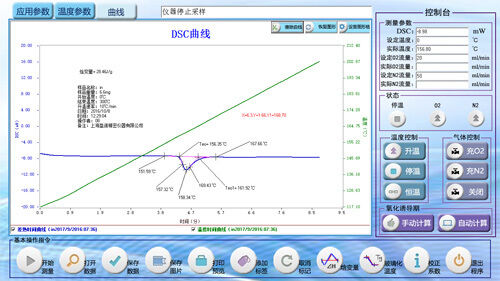

Q6: DSC 테스트의 표본 요구 사항은 무엇이며 데이터는 어떻게 처리됩니까?

권장된 샘플 무게는 2~10 mg (물질 종류에 따라) 이다. 기계는 고민성 열 흐름 센서 (민성 ≤0.1μW) 및 전문 분석 소프트웨어, 자동으로 테스트 곡선 (열량 흐름 대 온도 / 시간) 을 기록하고 주요 매개 변수를 계산합니다. 데이터를 추가 분석을 위해 Excel / CSV / PDF 형식으로 내보낼 수 있습니다.

Q7: DSC 기계에 어떤 유지 보수가 필요하며 핵심 부품의 사용 기간은 무엇입니까?

정기적 인 유지 보수에는 온도 및 열 흐름의 연간 캘리브레이션 (인디움과 같은 표준 참조 재료) 및 샘플 패스의 정기적인 청소가 포함됩니다.열/냉각 모듈) 의 사용 수명이 ≥501000번의 테스트 사이클을 통해

Q8: DSC 기계는 특정 테스트 필요에 맞게 사용자 정의 될 수 있습니까?

예, 확장 된 온도 범위 (저온 냉동 모듈 또는 고온 오븐), 전문 샘플 패스 (허메틱,압력 내성), 및 맞춤형 소프트웨어 기능 (예를 들어, 경화 반응을위한 운동 분석 모듈) 独特의 응용 시나리오에 적응.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!